With mrp mes at the forefront, this innovative integration of Material Requirements Planning (MRP) and Manufacturing Execution Systems (MES) is reshaping the landscape of modern manufacturing. As industries face increasing demands for efficiency and precision, the synergy between MRP and MES is proving to be a game changer, offering solutions that streamline operations and enhance productivity. This powerful combination not only optimizes resource management but also provides real-time insights, allowing manufacturers to respond swiftly to market changes.

The integration of these systems is not just a technological advancement; it’s a strategic necessity that enables companies to manage their inventories effectively while keeping production on track. Various industries, from automotive to electronics, are reaping significant benefits from this partnership, showcasing how MRP MES can drive success in today’s competitive environment.

Introduction to MRP and MES: Mrp Mes

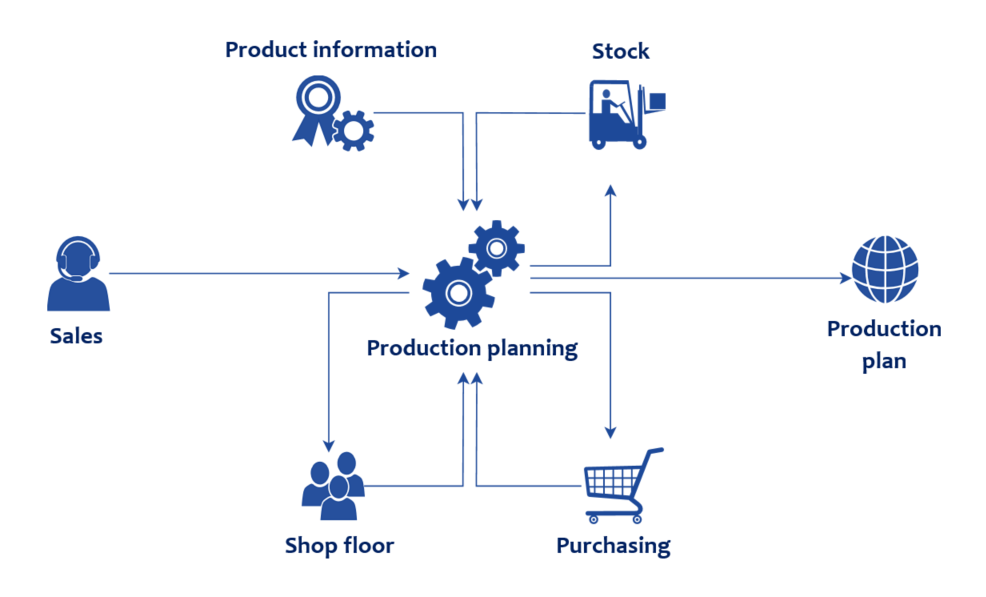

Material Requirements Planning (MRP) and Manufacturing Execution Systems (MES) are two pivotal components in modern manufacturing that streamline operations and enhance efficiency. MRP focuses on managing manufacturing processes by ensuring the right materials are available for production at the right time, while MES bridges the gap between enterprise resource planning (ERP) systems and the shop floor, providing real-time data on production processes.

The integration of MRP with MES brings about a significant transformation in how businesses operate. By aligning the planning capabilities of MRP with the execution functionalities of MES, manufacturers can optimize their production workflows, reduce lead times, and improve inventory management. This synergy allows companies to respond quickly to market demands and enhances overall productivity.

Industries Benefitting from MRP and MES Integration

Several industries experience substantial advantages from the integration of MRP and MES systems. The following sectors illustrate the diverse applications and benefits of this integration:

- Automotive Manufacturing: In this sector, MRP ensures that components are available for assembly lines, while MES tracks production progress and quality metrics in real-time, leading to optimized workflows and reduced downtime.

- Aerospace and Defense: These industries rely on stringent regulatory compliance and quality assurance. MRP helps manage complex supply chains, while MES provides detailed insights into manufacturing processes, ensuring that every component meets safety standards.

- Pharmaceuticals: The pharmaceutical industry benefits from precise control over raw materials and production processes. MRP assists in planning for ingredient availability, whereas MES monitors production conditions, ensuring compliance with health regulations.

- Electronics Manufacturing: The fast-paced nature of electronics requires real-time data for quick adjustments. MRP manages inventory levels, while MES provides immediate feedback on production performance, enabling swift responses to demand changes.

“The integration of MRP and MES not only enhances supply chain efficiency but also drives innovation in manufacturing processes.”

Through these examples, it is evident that the integration of MRP and MES systems empowers manufacturers across various industries to remain competitive in an ever-evolving marketplace.

Advantages of MRP MES Integration

The integration of Material Requirements Planning (MRP) and Manufacturing Execution Systems (MES) presents a transformative opportunity for production management. By synchronizing these two robust systems, manufacturers can streamline operations, optimize resource utilization, and ultimately enhance overall productivity. The collaborative synergy between MRP and MES enables real-time visibility and control, which is critical in today’s fast-paced manufacturing environment.

The benefits of combining MRP and MES extend across various dimensions of production management. This integration facilitates improved inventory management and boosts production efficiency, making it an essential strategy for manufacturers aiming to remain competitive. By ensuring that inventory levels are accurately aligned with production needs, businesses can minimize excess stock and reduce carrying costs.

Impact on Inventory Management and Production Efficiency

The integration of MRP and MES significantly enhances inventory management processes. This synergy optimizes the flow of materials, ensuring that the right quantity of materials is available at the right time. The impact becomes evident through several key advantages:

- Real-Time Inventory Tracking: MRP MES integration allows for the continuous monitoring of inventory levels. This real-time data aids in making informed decisions regarding stock replenishment and reduces the likelihood of stockouts or overstock situations.

- Reduced Lead Times: By synchronizing demand forecasts from MRP with the production schedule in MES, manufacturers can reduce lead times, enabling quicker turnaround on customer orders.

- Enhanced Accuracy: Automatic updates between MRP and MES minimize manual data entry, which in turn reduces human error and improves the accuracy of inventory records.

- Streamlined Supply Chain Management: The integration fosters better collaboration with suppliers, leading to timely deliveries and improved supply chain responsiveness.

Case studies from industry leaders illustrate the success of MRP MES integration. One notable example is a leading automotive manufacturer that implemented this integration to improve its production processes. Following the integration, the company reported a 30% reduction in inventory carrying costs, along with a 25% increase in production efficiency. These results stemmed from improved communication between departments, which allowed for more agile production planning and execution.

In another instance, a consumer electronics manufacturer achieved significant gains in operational efficiency through MRP MES integration. By leveraging real-time data analytics, the company reduced production downtime by 15% and improved on-time delivery rates to 95%. Such case studies highlight the tangible benefits of integrating MRP and MES, showcasing how it can lead to improved inventory management and enhanced production efficiency.

Implementation Strategies for MRP MES

Implementing MRP (Material Requirements Planning) and MES (Manufacturing Execution Systems) in a manufacturing environment is a multi-faceted process that requires careful planning and execution. The integration of these systems can streamline operations, enhance productivity, and improve inventory management. Understanding the steps necessary for successful implementation, comparing available software solutions, and addressing potential challenges are key to achieving a smooth transition.

The process of implementing MRP MES involves several critical steps that ensure a seamless integration. Each step contributes to the overall effectiveness of the system in managing production, inventory, and processes. Below are the key steps involved in the implementation process:

Steps for Implementing MRP MES

The implementation process can be categorized into a series of actionable phases:

- Needs Assessment: Identify specific business requirements and operational challenges that the MRP MES needs to address.

- System Selection: Evaluate and choose the appropriate MRP MES software that aligns with the identified needs.

- Planning and Design: Create a detailed implementation plan, including timelines, resource allocation, and system design.

- Data Migration: Transfer existing data into the new system, ensuring data accuracy and integrity.

- System Configuration: Customize the MRP MES software to fit the unique requirements of the manufacturing processes.

- Testing: Conduct thorough testing of the system to identify and resolve any issues before full deployment.

- Training: Provide comprehensive training for all users to ensure efficient use of the system.

- Go-Live: Launch the MRP MES into production while maintaining support for users during the transition.

- Post-Implementation Review: Evaluate the system’s performance and make necessary adjustments based on user feedback.

Comparison of MRP MES Software Solutions

To facilitate informed decision-making, below is a comparison table of notable MRP MES software solutions available in the market. This comparison showcases key features, pricing, and scalability options.

| Software | Key Features | Pricing | Scalability |

|---|---|---|---|

| Oracle NetSuite | Cloud-based, real-time analytics, integrated ERP | Starts at $999/month | Highly scalable for growing businesses |

| SAP S/4HANA | Robust analytics, IoT integration, global compliance | Custom pricing based on business size | Ideal for large enterprises |

| Microsoft Dynamics 365 | AI-driven insights, modular apps, user-friendly interface | Starts at $40/user/month | Flexible for small to medium-sized businesses |

| Plex Manufacturing Cloud | Real-time visibility, quality management, supply chain integration | Custom pricing available | Designed for manufacturers of all sizes |

Challenges Faced During Integration

Integrating MRP and MES systems can present several challenges that may hinder the effectiveness of the implementation. Identifying these challenges early on and developing strategies to overcome them is crucial for success. Common challenges include:

“Data Silos: Inconsistent data across different departments can lead to inefficiencies and errors.”

The existence of data silos can create discrepancies and hinder data flow between systems. To overcome this, organizations should invest in data standardization practices and ensure that all departments utilize the same data sources.

“Resistance to Change: Employees may be reluctant to adapt to new systems or processes.”

To mitigate resistance, it is essential to involve employees early in the decision-making process and provide adequate training to demonstrate the benefits of the new system.

“Integration Complexity: Merging two distinct systems can be technically challenging.”

Employing experienced IT professionals and utilizing integration tools designed for MRP and MES can streamline the integration process, minimizing technical challenges.

By employing systematic strategies for implementation, comparing available software solutions, and addressing challenges proactively, organizations can successfully integrate MRP and MES systems, ultimately enhancing their manufacturing capabilities.

Future Trends in MRP and MES

The landscape of Material Requirements Planning (MRP) and Manufacturing Execution Systems (MES) is evolving rapidly, driven by advances in technology that foster greater efficiency and flexibility in production environments. As industries adapt to new market demands and competitive pressures, understanding these future trends is crucial for organizations looking to maintain an edge in manufacturing operations.

Emerging technologies are set to reshape the functionalities of MRP and MES significantly. Innovations such as the Internet of Things (IoT), artificial intelligence (AI), and advanced data analytics play pivotal roles in enhancing system capabilities, streamlining processes, and improving decision-making frameworks. These advancements facilitate seamless integration and real-time insights, allowing manufacturers to respond swiftly to fluctuations in demand and operational challenges.

Emerging Technologies Influencing MRP and MES

The integration of emerging technologies into MRP and MES systems is transforming how manufacturers approach production planning and execution. Key technologies contributing to these changes include:

- Internet of Things (IoT): IoT devices provide real-time data from machinery and production lines, allowing for better monitoring and control of manufacturing processes.

- Artificial Intelligence (AI): AI algorithms analyze vast amounts of data to optimize inventory levels, forecast demand accurately, and predict maintenance needs.

- Cloud Computing: Cloud-based MRP and MES solutions offer scalability, flexibility, and remote access, making it easier to adapt to changing operational requirements.

- Blockchain Technology: Blockchain enhances traceability and transparency in supply chains, ensuring secure and efficient transactions between stakeholders.

Artificial Intelligence Enhancements in MRP and MES

The adoption of AI within MRP and MES systems is poised to take operational efficiency to new heights. By leveraging machine learning and predictive analytics, organizations can enhance various functionalities:

- Demand Forecasting: AI algorithms improve the accuracy of demand predictions by analyzing historical sales data and market trends, leading to optimized inventory management.

- Production Scheduling: AI can automate scheduling tasks by considering numerous variables, including machine availability, workforce capacity, and order priorities, ensuring timely production runs.

- Predictive Maintenance: Using AI to analyze equipment data allows for the proactive identification of potential failures, reducing downtime and maintenance costs.

- Quality Control: AI-powered image recognition can automate quality inspections, identifying defects more accurately than human inspectors.

Role of Data Analytics in Optimizing MRP and MES Systems

Data analytics serves as a cornerstone in optimizing MRP and MES operations, providing actionable insights that drive efficiency. The use of advanced analytics tools enables manufacturers to harness data effectively, guiding strategic decisions:

- Performance Metrics: Analytical tools help track key performance indicators (KPIs), allowing organizations to identify areas for improvement and streamline processes.

- Inventory Management: Data analytics facilitate real-time inventory tracking, preventing stockouts and overstock situations by providing insights into optimal inventory levels.

- Supply Chain Optimization: By analyzing data across the supply chain, companies can enhance collaboration, reduce lead times, and improve overall responsiveness.

- Operational Efficiency: Data-driven insights help identify bottlenecks in production, enabling manufacturers to optimize workflows and enhance throughput.

Helpful Answers

What is the primary function of MRP?

The primary function of MRP is to manage inventory levels and ensure that materials are available for production while keeping costs low.

How does MES improve production processes?

MES improves production processes by providing real-time data that helps monitor operations, track performance, and optimize workflow management.

What industries are best suited for MRP MES integration?

Industries such as automotive, electronics, pharmaceuticals, and food processing are particularly well-suited for MRP MES integration due to their complex supply chains and production requirements.

What challenges arise during MRP MES implementation?

Challenges during implementation can include resistance to change, integration with existing systems, and the need for employee training on the new processes.

How can data analytics enhance MRP MES systems?

Data analytics can enhance MRP MES systems by providing insights into production trends, optimizing inventory levels, and predicting maintenance needs, leading to improved decision-making.